Grass Buffer Strip

The barn at the home farm at Glen Osprey

is located, like many of its vintage, in close proximity to a

water course, in our case the Noisy River. The slope from the

barn to the river, some 300 feet away, means that there is a flow

of nutrients from the barnyard into the stream. Over the years

eves troughs have been constructed to reduce the runoff as well

as a concrete retaining wall for the manure pile but there remained

a significant flow of materials down the slope to the stream as

indicated by the following photo:

|

|

The Healthy Waters program, provided through the Nottawasaga Valley Conservation Authority, was used to fund a buffer strip between the barn and the river in 2001. Reed Canary and Orchard Grass was seeded with a nurse crop of mixed grain in the buffer area and an electric fence was erected to restrict the cattle. The forage crops that make use of the high levels of nutrient in the soils are harvested annually as round bale sileage leaving an aftermath growth of 20 to 30 cm for the winter to restrict the direct flow of water down the slope. The following photo shows the results of the planting:

While this project does not completely resolve the problem, it has significantly reduced the nutrient load on the Noisy River at a cost of only $140, a price well within the means of any farm enterprise. There is the added advantage of the forage crop, harvested twice a year. This small plot of 0.67 acres is capable of producing 10 (4 x 5) round bales per season. The only disadvantage is the volume of the stand requires either a VERY slow haybine cutting speed or the use of a discbine. Also the heavy crop is difficult to dry and wrapped sileage bales provide for better nutrient retention.

Invoices:

Simcoe Co-op - May 24, 2001 Reed Canary Grass @$3.34/lb

Simcoe Co-op - May 22, 2001 Gate handles@$1.99

Simcoe Co-op - April 30, 2001 Fence tighteners@ $3.99

Simcoe Co-op - May 31, 2001 Fence wire 1,900ft @$67.59

Highland Supply - Apr 27, 2001 Insulators @ $0.10 each

Highland Supply - Apr 27, 2001 End insulators @$1.30

ProRich Seeds - May 12, 2001 Pasture mix @ $4.85/lb

Area of Buffer

0.67 acres

Seeding Rates

Pasture mix = 10lb/acre = 6.7lb x $4.85/lb = $32.50

Reed Canary = 12lb/acre = 8lb x $3.34/lb = $26.72

Total seeding cost = $59.22

Electric Fence

Length of 360 feet with 4 strands of high tensile wire

Total wire length 1,440 ft (1,440 ft x 67.59)/1900ft = $51.23

24 insulators @ $0.10 = $2.40

8 end insulators @ $1.30 = $10.40

4 fence tighteners @ $3.99 = $15.96

1 gate handle @$1.99 = $1.99

8 fence posts cut from farm bush = $0.00

Total Fencing costs = $81.98

Total cost for project = $141.20

To a casual observer, especially during the winter an spring months, the cattle in the barn yard and the cows in the winter quarters, would appear to pose a significant risk to the water quality of the Noisy River only a short distance down a slope from these locations. Perhaps some observers might have the opinion that the only possible solution to this perceived problem may be in the form of extensive and expensive manure containment facilities.

Water samples from the Noisy River were taken from three locations (see #4 and #5 on aerial map - sample 1 location is not in the photo) in March, 2003 and repeated at the same locations in May of 2003. Unfortunately, similar stream water sampling was not conducted prior to the grass buffer being installed.

|

sample #2 sample #2 |

|

The results, anylized at Agri-Food LAboratories, Guelph, are summarized here:

|

|

|

|

|

|

|

|

A1 | 7.80 | 4.06 | <1.0 |

|

|

A2 | 8.00 | 4.21 | <1.0 |

|

|

A3 | 8.10 | 4.22 | <1.0 |

|

|

A1 | 7.70 | 10.00 | <1.0 |

|

|

A2 | 7.90 | 7.00 | <1.0 |

|

|

A3 | 8.00 | 6.00 | <1.0 |

While these results are not truly scientific because too few samples were taken to provide great accuracy, I do believe that some reasonable assumptions can be made. The low levels of phosphorous indicate that there has been minimal stream contamination of this element from the manure present in the barn yard and from the wintering field of the mature cows. There are perhaps two reasons for this, the first being phosphorous' poor ability to migrate via leaching usually relying on soil particle migration, with the second being the forage's capture of this element in the growing process.

The nitrate results are also encouraging. The March tests did indicate that there was an increase and therefore some stream nitrate contamination as the water flowed through the farm but the levels are not high and showed only a moderate increase. The May test was more interesting because, while the nitrate levels were almost two times that of the March test, there was a dramatic DECREASE in nitrate levels from a high of 10ppm where the stream entered the farm to a low of 6ppm where it left. These preliminary tests seem to indicate that the water quality actually IMPROVED as the Noisy River flowed through our farm not a conclusion that a casual observer may have made.

It is important to restate here that this forage must be harvested and taken away from the site to provide for the constant depletion of nitrates and phosphates from this area. Pasturing a buffer strip would not allow the transfer of nutrients from the site.

Glen Osprey Farm has utilized a number of different alternate watering devices as a means of keeping our cattle away from water courses and ponds. Some of these devices have been quite successful and require little or no maintenance while others have been bad investments and have been rejected.

I shall start with the least successful, a Sling Pump, that we purchased as one of the very first means of pumping water from the Noisy River to a stock tank at the edge of the buffer fence at location #5 on the aerial map.

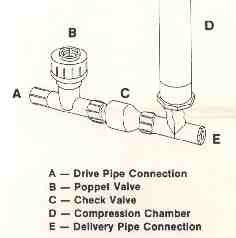

Inside the nose cone of the sling pump is a coil of plastic pipe. As the running water rotates the cone, the open end of the pipe at the large end alternately picks up air and water that eventually migrates to the smaller end of the cone. It is the now compressed bubble of air at the small end of the cone that provides the pressure to pump the water to a height.

There were two major problems with this pump for our situation:

The first was the speed at which the water was flowing. The speed of rotation was directly proportional to the volume of water pumped and the height of delivery. In our case the height was 3 meters ( 15 feet). I was able to increase the flow speed of the water by making a channel using meter cubed concrete blocks, the kind you can purchase from any concrete supply company, and some water was supplied to the tank. Unfortunately the volume was not sufficient for our needs.

The second was the hardness of our stream water. It was not long before a lime build up occurred on the blades of the propeller but it was the lime deposit on the rotating shaft that eventually rendered this unit completely useless. Perhaps if the stream had a pH of 7 or less, this unit would have proven successful for us.

Sling Pumps can be purchased from the US at $575.00. [http://www.riferam.com]

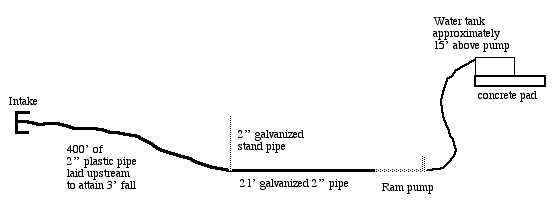

There are two ram pumps used on our farm, the first was installed in 1993 at location #2 on the aerial map. Originally we had hoped to have this unit supply water for a group of Highland cows that were wintered in this field and the unit was insulated with a wooden box to prevent it from freezing. This was successful but I should have removed the boxes prior to the spring floods! The highland herd is now sold and there is no requirement to provide water during the winter.

After 10 years the only repairs that have been made are to the poppet valve where the metal sealing wring had become worn. With the home farm unit, we ran a 400 foot length of plastic pipe up the stream in order to obtain the required minimum of a three foot fall of water. The volume of water pumped and the height to which the water can be pumped is directly proportional to the head of water that can be obtained. The few problems that we have had with this system are mud deposits in the line and objects, including more than one crayfish, that have jammed the poppet valve. The easiest way to clean the line is with my Honda transfer pump. As with all watering facilities, these units should be checked on a daily basis to ensure that they are working properly.

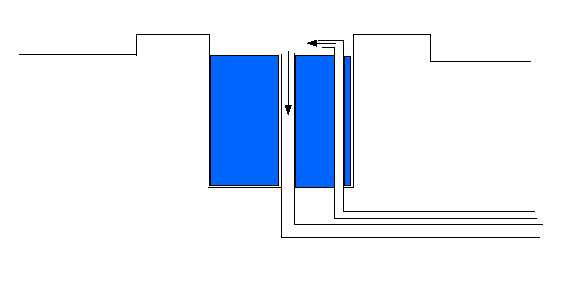

A second ram pump was installed at our pasture farm using a Healthy Waters grant from the Notawassauga Valley Conservation Authority. As with the first pump we had designed the system using a length of pipe run up a small outflow stream from a farm pond. Unfortunately this setup did not provide enough volume of water for the 30 cow calf pairs that were being watered. Fortunately, the pond was designed with a bottom outlet as shown below.

Not wanting to be swept through the culvert if the 4 x 4 cedar posts that formed the dam broke while I was drilling the 2" hole for the intake pipe, I waited until late in the season when the water level in the pond had receeded to a more safe level. As it was, I still had myself secured by a rope for safety's sake. There was more than enough flow of water once this system was put into place with the added advantage of the overflow from the water tank returning to the pond. The pond, which once had direct access by the cattle, has now been fenced and planted with a mix of maple, walnut, spruce, ash, and cedar again through a Healthy waters grant. This pond buffer not only provides a better water quality, free of fecal contaminants, for the cattle but also creates a protected area for duck nesting and enhances the natural beauty of the pond.

Both ram pumps were purchased from Fleming Company, http://www.theramcompany.com, the latest unit at $385.23 CDN.

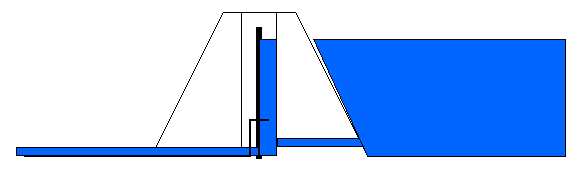

When the first ram pump was installed in 1993 we also installed a gravity feed system to supply water to our mature cows during the winter. Prior to this installation the cows had accessed the Noisy river directly via a small side stream that had been constructed before we purchased the farm in 1972. As with the ram pump, we used the natural fall of the river as it flowed through the farm and placed a 4" plastic tile line in the stream until we had reached a height above our water station of about 3 feet. In retrospect we should have gone further up the river to create a greater head of water and we would have been able to place the water tank further from the stream.

To prevent freezing of the water during the winter we used a 3 foot concrete well tile cemented at its base with in inlet and an outlet as shown on the diagram. This tile was then encased in a concrete pad.

The gravity water system is the most trouble free type of alternate watering facility that we have. The only problems we have are at the intake where river debris sometimes blocks the screen and a few broken connections at the lower end where the 4" tile is reduced to a 2" plastic pipe. To prevent the cattle from inadvertantly placing their feet in the tank and damaging the intake and outflow pipes, we have welded a heavy support sreen that sits a few inches below the water line. This unit is checked daily when the cattle are fed. There has never been a problem with freezing but the snow does form a cover on stormy days that has to be shovelled. At the end of the winter the build up of compacted snow around the tank forces the cows to go down on their knees to reach the water, the result of not providing a larger head of water when we first constructed the system.

|

|

At our pasture farm in Grey County we have a four dugout ponds that supply water for the cattle during the summer pasture season. At first the cattle were allowed direct access to these ponds but the limited pond size made them easily fouled by the cattle. To remedy this situation we purchased two nose pumps of French design and built a rough support structure for them adjacent to the ponds. These units worked well but their design allowed for a large amount of splash water around the pumps. This soon developed into a mud slurry around the pumps and we were constantly drawing in fill to replace the hole left around the pumps.

We have found that one pasture pump would service, at maximum, 20 cow calf pairs but even with this number two pumps should be used because of the tendancy of cattle to come to the water in a large group. The two pumps relieve some of the jostling around the water source. It is highly recommended that the pasture pump be installed on a concrete pad. When we did this I also designed a low, 5", concrete catch basin around the pump to attempt to reclaim some of the splashed water. My design was not perfect as most of the water is splashed toward the cow as the nose section swings back. Constructing a wider 5" tcatch basin and suspending the pump within it might resolve this problem.

Both types of nose pumps are able to draw water from a height of at least 3 meters as long as a foot valve is used. To ensure the proper seating of the foot valve the valve and input line should be placed vertically in the water.

We have used two types of nose pumps, the first and oldest being from a French manufacturer, Aquamat, the second from a Brazilian company, Jacto, that, very unfortunately, no longer manufactures nose pumps. The Brazilian unit was a much stronger and heavier nose pump and has not had the degree of wear that the French units have.

|

|

Glen Osprey Farm has a 150 acre pasture farm in Grey County at the junction of county road 4 and highway 124. We also rent 50 acres from the adjacent farm to the west. Normal pasture season has three purebred cow herds pastured on these fields so there is a requirement for good electric fencing to keep the cow herds and their respective bulls separate. The farm also has a very long boarder with the very busy #124 highway, another important reason for good fencing. For many years a hydro service had been available to a small barn at the north end of the farm that was used almost exclusively to run the powered fencer. Unfortunately, the barn foundation reached a state where either repairs were required or the barn would have to be torn down. Repairs were too costly but that meant that the hydro service would either have to be relocated or replaced. At that time our monthly hydro service costs were $52.00.

A solution to this problem was the installation of a small solar power system that we located adjacent to one of the farm ponds. This particular pond usually serviced the largest herd of cattle and the two nose pumps were just able to keep up with the demand. To supply the power to only run the fencer would have required a smaller solar collector but we decided to purchase a 120 watt panel so that sufficient power would be generated to run a small water pump as well.

Photo shows the Gallagher

BEV II fencer and the two Deep Charge Marine Batteries from Canadian

Tire @$100 each = $200CDN. In retrospect I should have purchased

batteries more compatible with the solar collector and will do

so once these units are no longer of use. Above the batteries

is a 300 watt power inverter, again from Canadian Tire @ $85.00.

This power inverter is required to run the AC 110 volt Gallagher

fencer. The output of this AC fencer has been reduced by about

5% using the power inverter but is still a far better unit to

power the fence than any 12 volt battery unit.

Photo shows the Gallagher

BEV II fencer and the two Deep Charge Marine Batteries from Canadian

Tire @$100 each = $200CDN. In retrospect I should have purchased

batteries more compatible with the solar collector and will do

so once these units are no longer of use. Above the batteries

is a 300 watt power inverter, again from Canadian Tire @ $85.00.

This power inverter is required to run the AC 110 volt Gallagher

fencer. The output of this AC fencer has been reduced by about

5% using the power inverter but is still a far better unit to

power the fence than any 12 volt battery unit.

The charge controller is the small black box between the fencer

and the red shut off switch, $85.50 USD. This controller regulates

the charge to the batteries so that they do not become overcharged

during the day or leak charge to the panel at night. The controller

will also prevent the water pump from depleting the batteries

at night giving priority to the fencer.

There have been some problems during extended cloudy days with maintaining a good charge in the two batteries. This might be rectified by better quality batteries or the addition of an extra battery.

Water pump, not shown, $140.00CDN. This is a 12 volt unit from the TSC Store. This pump is controlled in the tank by a floating switch.

My cost in Canadian dollars for the panel and controller including delivery was $1,089.00 from Arizona Light and Power http://www.solar-electric.com. I had checked with Canadian suppliers but they could not match this price. As of Feb. 2004, the Kyocera 120 watt panel is priced at $474 USD from the same distributor.

Cost

Panels and controller $1,089.00

Batteries $200.00

Power Inverter $85.00

Water pump $140.00

Total $1,514.00